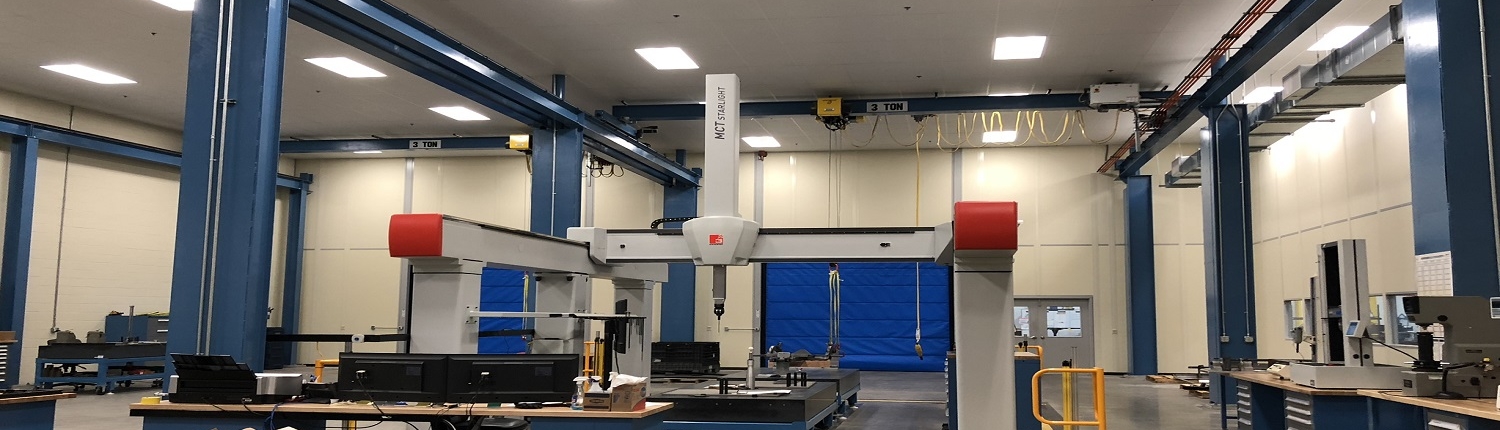

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe.

CMM rooms are designed to keep highly intricate CMM machinery operating within a specific calibrated tolerance range. CMM rooms require a constant and consistent temperate and humidity range to insure the CMM measurements are accurate. The proper temp and humidity insures that there will be minimal machine or part expansion or contraction. If the temperature or humidity within the room changes +/- out of tolerance, the machine may need to be recalibrated, costing time and money.

As part of the overall design phase, we offer specific HVAC options to control the temperature and humidity in your CMM room to your own custom level.

Modular CMM rooms can be deconstructed and moved saving time and money vs conventional construction.

A modular enclosure for a CMM room is a great way to demonstrate quality assurance standards to visitors and customers as an important investment in CMM quality control.

Advantages & Benefits of Modular Construction

- All material is pre-cut, mitered and completely finished. No taping, sanding or painting.

- The installation of a modular office building is completed in a fraction of the time of permanent construction. Saves time, money and taxes.

- You get the tax advantage of 7 year depreciation as opposed to 39 years required with conventional construction.

- Load bearing capabilities, including 40′ clear spans.

- Easy to move to a new location.

- Easy to reconfigure to meet your changing modular office needs.

- Wall finishes include steel, aluminum, FRP, vinyl covered gypsum and hardboard.

For our other material handling products please try: www.powerandmotion.com